- Domov

- >

- Produkty

- >

- Oceľ X40CrMoV5-1

- >

Oceľ X40CrMoV5-1

Oceľ X40CrMoV5-1, ako oceľ na výrobu foriem na tvárnenie za tepla, sa vyznačuje vynikajúcou kombináciou vysokoteplotných vlastností, ktorá spája vysokú húževnatosť a pevnosť pri vysokých teplotách, vďaka čomu je obzvlášť vhodná pre opakované tepelné cykly, ako sú napríklad tlakové liatie foriem. Oceľ X40CrMoV5-1 prechádza procesom elektrotroskového pretavovania, aby sa zabezpečila rovnomernosť materiálu, a vďaka optimalizovanému procesu tepelného spracovania môže dosiahnuť tvrdosť 48 – 52 HRC. Oceľ X40CrMoV5-1 má vynikajúcu odolnosť voči tepelnej únave, erózii zliatin hliníka a medi a extrémne nízku mieru deformácie pri tepelnom spracovaní. Po povrchovej nitridácii môže tvrdosť dosiahnuť HV1000 alebo vyššiu, čo výrazne predlžuje životnosť formy.

- Fucheng Steel

- Čína

- 1 mesiac

- 2000 ton/mesiac

- informácie

- Video

NÁSTROJOVÁ OCEĽ X40CrMoV5-1

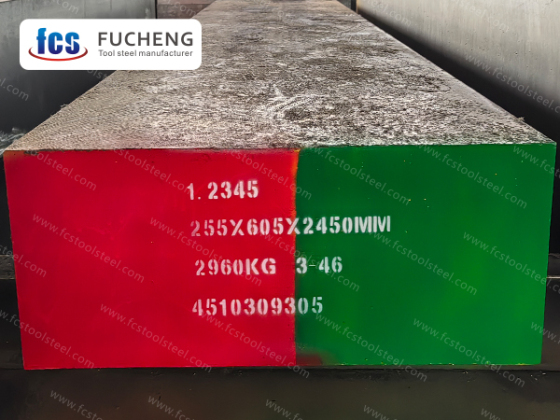

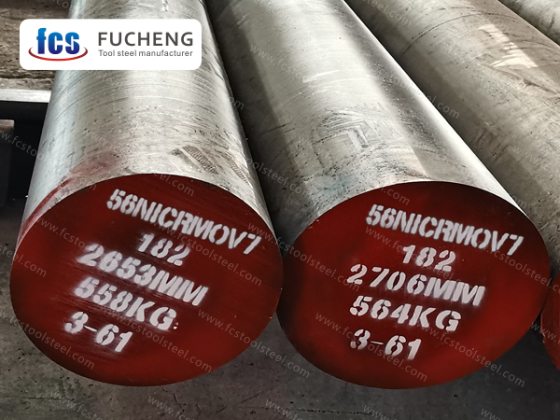

| Metóda tavenia a výroby: | LF+VD+ESR+Kované |

| Stav dodania: | Žíhané |

| Tvrdosť pri dodaní: | ≤235 HBS |

| Testovací štandard UT: | September 1921-84 Trieda 3 D/d,E/e |

POROVNANIE TRIEDY OCELE X40CrMoV5-1 A POROVNANIE CHEMICKÉHO ZLOŽENIA

| Štandardná/trieda ocele | Chemické zloženie (%) | ||||||

| C | A | Minnesota | Kr | Pre | V | ||

| DIN/W-č. | X40CrMoV5-1/1.2344 | 0,35~0,42 | 0,90~1,20 | 0,30~0,50 | 4,80~5,50 | 1,20~1,50 | 0,90~1,15 |

| ASTM | H13 | 0,32~0,45 | 0,80~1,20 | 0,20~0,50 | 4,75~5,50 | 1,10~1,75 | 0,80~1,20 |

| ON | SKD61 | 0,35~0,42 | 0,80~1,20 | 0,25~0,50 | 4,80~5,50 | 1,00 – 1,50 | 0,80 ~ 1,15 |

APLIKÁCIA

Oceľ X40CrMoV5-1 zohráva dôležitú úlohu v oblasti výroby foriem na tlakové liatie a je obzvlášť vhodná na tlakové liatie neželezných kovov, ako sú zliatiny hliníka a horčíka. Oceľový materiál X40CrMoV5-1 vykazuje vynikajúcu stabilitu vo vysokoteplotnom prostredí a odoláva náročným prevádzkovým podmienkam opakovaného zahrievania a chladenia, čím účinne zabraňuje tepelným únavovým trhlinám na povrchu formy a zaisťuje dlhodobú spoľahlivosť.

Oceľ X40CrMoV5-1 sa bežne používa pri výrobe kovacích a extrúznych foriem. Jej vynikajúca rázová húževnatosť a odolnosť proti opotrebeniu jej umožňujú odolávať obrovskému mechanickému namáhaniu počas procesov tvárnenia kovov. Oceľ X40CrMoV5-1 si dokáže udržať rozmerovú presnosť formy aj za nepretržitých vysoko intenzívnych pracovných podmienok, čím výrazne predlžuje životnosť nástrojov.

Oceľ X40CrMoV5-1 sa tiež široko používa pri výrobe kľúčových komponentov pre vstrekovacie formy na plasty. Po vhodnej úprave môže povrch formy dosiahnuť vynikajúcu odolnosť proti korózii a účinne odolávať erózii plastovej taveniny. Oceľ X40CrMoV5-1 je obzvlášť vhodná na spracovanie korozívnych technických plastov, čím zabezpečuje kvalitu povrchu a rozmerovú stabilitu výrobku.

X40CrMoV5-1CHARAKTERISTIKA OCELE

Oceľ X40CrMoV5-1 je vysokokvalitná oceľ na tvárnenie za tepla, známa svojou vynikajúcou stabilitou pri vysokých teplotách a komplexnými mechanickými vlastnosťami. Oceľ X40CrMoV5-1 sa široko používa vo vysokoteplotných pracovných podmienkach, ako sú formy na tlakové liatie a formy na kovanie za tepla, a zaujíma dôležité miesto v európskom priemyselnom systéme.

Oceľ X40CrMoV5-1 používa legujúci pomer 5 % chrómu, 1,3 % molybdénu a 1 % vanádu, čím vytvára stabilnú karbidovú sieť. Táto konštrukcia zliatiny umožňuje udržiavať pracovnú tvrdosť viac ako 40 HRC aj pri vysokých teplotách 600 ℃, čo je výrazne lepšie ako pri bežnej lisovacej oceli. Miera zachovania pevnosti pri vysokých teplotách môže dosiahnuť viac ako 85 %, čo je obzvlášť vhodné pre scenáre kontinuálnej prevádzky pri vysokých teplotách, ako je napríklad tlakové liatie hliníkových zliatin.

Proces tepelného spracovania ocele X40CrMoV5-1 je kľúčový pre jej výkon. Odporúča sa použiť kalenie v oleji pri teplote 1020 – 1050 ℃ a sekundárne popúšťanie pri teplote 580 – 630 ℃, aby sa dosiahla najlepšia rovnováha medzi tvrdosťou a húževnatosťou. Po štandardizovanom tepelnom spracovaní môže tvrdosť materiálu dosiahnuť 50 – 54 HRC a rázová húževnatosť sa udržiava na úrovni 25 – 30 J/cm², čo spĺňa požiadavky väčšiny foriem na tvárnenie za tepla.

Pokiaľ ide o spracovateľský výkon, oceľ X40CrMoV5-1 vykazuje dobrú obrobiteľnosť v žíhanom stave. Oceľ vyrobená procesom elektrotroskového pretavovania (ESR) má vyššiu čistotu a drsnosť povrchu po leštení môže dosiahnuť Ra 0,05 μm alebo menej. Predkalená verzia (28 – 32 HRC) sa dá priamo presne obrábať, čo výrazne skracuje cyklus výroby foriem.

Pokiaľ ide o odolnosť voči tepelnej únave, oceľ X40CrMoV5-1 výrazne zlepšila svoju schopnosť odolávať šíreniu tepelných trhlín optimalizáciou rozloženia karbidov. Praktické aplikačné údaje ukazujú, že životnosť hliníkových foriem na tlakové liatie je o 30 – 40 % dlhšia ako u bežnej ocele H13, čo efektívne znižuje frekvenciu údržby foriem a prestoje vo výrobe.

Odolnosť ocele X40CrMoV5-1 proti korózii je spôsobená ochranným účinkom 5 % obsahu chrómu, ktorý jej umožňuje odolávať erózii roztaveného kovu a chladiaceho média. Povrchová úprava je však stále potrebná na zvýšenie ochrany v prostredí s obsahom síry alebo vysokého obsahu chlóru. Po nitridácii je možné ďalej zlepšiť tvrdosť povrchu a odolnosť proti opotrebovaniu a HV môže dosiahnuť viac ako 1200.